Between Artificial Intelligence and Concreteness,

the state of art in Tumbling and Vibratory Finishing

We asked « Gemini.google.com »:

What is the state of the art of tumbling and vibratory finishing in Europe?

Here is the response by AI:

The state of art of tumbling and vibratory finishing in Europe is characterized by a continuous search for efficiency, sustainability, and adaptation to new technological challenges, such as additive manufacturing. Below is a summary of the latest trends and developments:

- Automation and Integration 4.0:

- Robotics and Robotic Cells: The integration of robots into vibro-finishing plants is a growing trend. These systems allow the automation of loading and unloading of the parts, optimizing the process and reducing reliance on manual labor, resulting in savings of time and resources.

- Combined systems: Plants are developed in order to combine vibrofinishing with other complementary processes such as laser marking, washing, or protection, to offer complete and automated solutions.

- Monitoring and control: Digitalization and integration with the principles of Industry 4.0 enable more precise monitoring of process parameters and greater optimization to ensure quality and productivity.

- Sustainability and Reduction of Environmental Impact:

- Dry processes: The possibility of implementing dry finishing processes is being explored to reduce water consumption, sludge production, and the need for wastewater treatment, with significant environmental and economic benefits.

- Low environmental impact treatments: The focus is on the use of materials and treatments that are less harmful and compliant with environmental regulations, such as passivation with Chromium III instead of Hexavalent Chromium.

- Recycling and recovery: Solutions for the recycling of abrasive materials and the optimization of waste management resulting from finishing processes are being studied.

- Finishing of Components from Additive Manufacturing:

- The growing spread of additive manufacturing (3D printing) has created a new need for surface finishing of parts with complex geometries and often rough or irregular surfaces.

- The tumbling and vibratory finishing are adapting to these new challenges, developing specific processes and suitable abrasive media means to optimize roughness, remove supports, and improve the aesthetic appearance of these components..

- Innovation in Abrasive Tools and Specific Processes:

- Advanced abrasive materials: New abrasive materials with specific characteristics (e.g., garnet with high specific weight and irregular grain structure) are being developed to ensure effective deburring, grinding, and polishing, even on complex geometries.

- Innovative Technologies: There are new technologies such as ‘Eccentric Finishing’ and ‘Carving Finish’ that promise precision finishes with greater effectiveness and noise reduction.

- The technology « VibroBLAST » combines vibro-finishing and sandblasting into a single process.

Specific processes: Processes are optimized for particular applications, such as grinding or ball polishing.

- Evolving Application Sectors:

- Tumbling and vibro-finishing remain fundamental in traditional sectors such as automotive, precision mechanics, jewelry, and cutlery. However, their application is expanding to new sectors, such as the medical field, thanks to the ability to achieve precise and hygienically suitable finishes.

- R&D:

- European companies in this field are constantly investing in R&D to improve process efficiency, reduce costs, optimize quality, and respond to the demands of an ever-evolving market. This includes collaborations with universities and project partners to develop tailor-made products and cutting-edge solutions.

In summary, the European tumbling and vibrofinishing industry is moving towards automation, sustainability, adaptation to new production technologies (such as additive manufacturing), and the development of innovative solutions for precision finishing, while maintaining a strong focus on quality and competitiveness.

Continuing in the research, Google’s Gemini offers further insights that we leave to the reader’s discretion to explore, if they wish. We then asked Paolo Redaelli, C.E.O. of Rollwasch® Italiana, about his opinion on the quality and completeness of the response provided by Gemini.

The point of view of CONCRETENESS

Paolo Redaelli represents the second of three generations of the Redaelli family, which founded and developed the concrete reality of Rollwasch® Italiana, a 100% italian company established in Italy 75 years ago, on Argelati Street in Milan – today an innovative Lombard SME and a pride of Italian manufacturing in the Vibrofinishing sector.

Paolo Redaelli’s perspective is based on the concrete ability to innovate, thanks to three fundamental drivers:

- Experience

- Creativity

- Passion

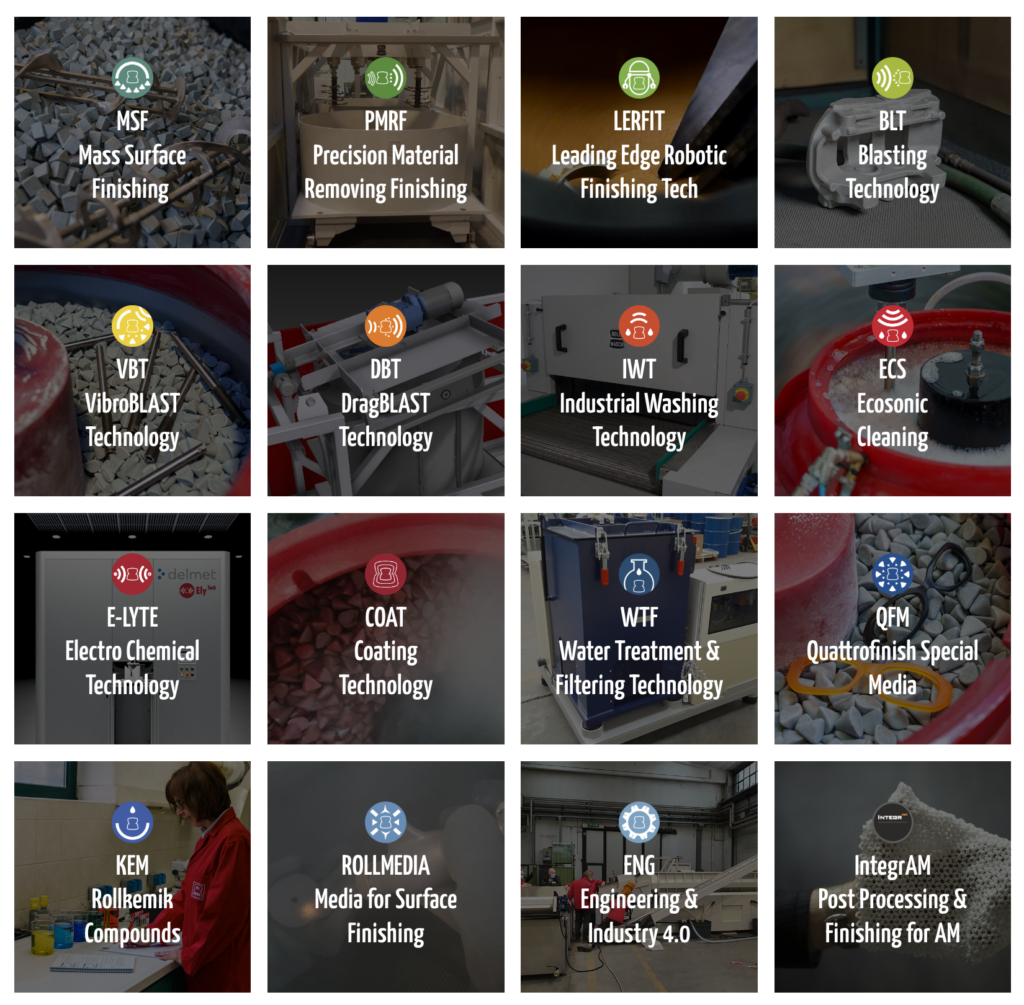

Gemini’s response, when talking about innovative technologies in Europe, does not include a long list of innovations (among a few can be traced back to the Lombard company), but all the technologies mentioned are actually patents and exclusive solutions of Rollwasch® Italiana:

Gemini talks about:

‘Eccentric Finishing’ and ‘Carving Finish’ promises: precision finishing with greater efficiency and noise reduction.

These two technologies are part of a macro area of specialization of Rollwasch® Italiana called PMRF – Precision Material Removal Finishing, a variant of the mass finishing process that allows components to be fixed to specific supports or frames for treatment, achieving highly precise and localized results.

Gemini also states:

« The technology ‘VibroBLAST’ combines vibro-finishing and sandblasting into a single process. »

In fact, in the first decade of the third millennium, Rollwasch® Italiana begins to pay more attention to the development of additive manufacturing/3D printing technologies and to seek a technology capable of addressing and solving the two main domains of this sprawling technology: Polymers and Composites on one hand and Metals on the other. From a long research and development activity, which sees Rollwasch® Italiana at the forefront of a considerable series of international patent applications, a new generation of finishing ‘media’ called ‘Quattrofinish’ is born, capable to face the new challenges of 3D Printing (but not only). A new family of vibratory finishing machines called VibroBLAST, destined to revolutionize both the fields of vibratory finishing and sandblasting, forever.

Gemini also mentions, in the third point of its response: Finishing of Additive Manufacturing Components.

To dedicate more attention to this important sector, Rollwasch® Italiana decided in 2019 to establish a Network of Companies, called IntegrAM, that would focus exclusively on this area of specialization.

Thanks to additional patented technologies from one of the partners in this network, Rollwasch® Italiana has begun producing machines and systems for:

- Dry saturated steam dyeing, using Steam DYEING technology, capable of dyeing polymer or composite components in 3D printing while consuming 10 to 20 times less color and up to 7 times less water.

- Eco SONIC ultrasonic washing, capable to perform specific defined phases of ‘Pre-Washing’, removal of hanging burrs and cleaning in ‘difficult’ areas, thanks to the ‘Dual Frequency’ technology of innovative sonotrodes.

- All SurfPRO surface preparation or finishing systems by IntegrAM are equipped with the innovative sensor WS, Wear Sensor. This device is able to inform the user about the state of the wear of the anti-abrasive lining, several months in advance of its total wear out.

The merger of Rollwasch Patents with those of the established business network has generated further exclusive and revolutionary technologies, such as:

- The multitasking finishing processes « MicroFLUID« , able to use a single « vector media » with extremely low wear, while a technological dosing station feeds various types of gels that carry abrasives – AbraGEL, alternated with rinses and completed by a final wash with specific detergent liquids. The results of this technology, which until a few years ago could only be achieved by using three, four, or five vibratory finishing machines with different media in cascade, allow:

- Total automation of long and complex processes

- Achieving super finishes of the highest level

- drastic reduction of liquid consumption (hence the name ‘MicroFLUID’)

- Containment of mud generation

- The robotic finishing processes « WaveFINISHING », particularly specialized for the aerospace sector, can finish all the turbine blades of a Bladed Disk (or Blisk) of an aircraft engine in just 3.5 hours – completely dry process and with a noise level below 65 DbA.

- The VibroDRY finishing processes, part of a patent called ‘Fluid Bed Mass Finishing’, ensure superior results with the complete absence of water, minimal waste and mud emission. Complete operative safety thanks to efficient suction and filtration systems classified Atex – external zone 22.

The concreteness of the challenging and ongoing R&D activities that Rollwasch® Italiana has developed over the last twenty years undoubtedly exceeds the expectations of Artificial Intelligence, providing Italy, Europe, and the world (duty permitting) with solutions in line with environmental sustainability, the needs of industry 4.0 and beyond.

For further information visit: