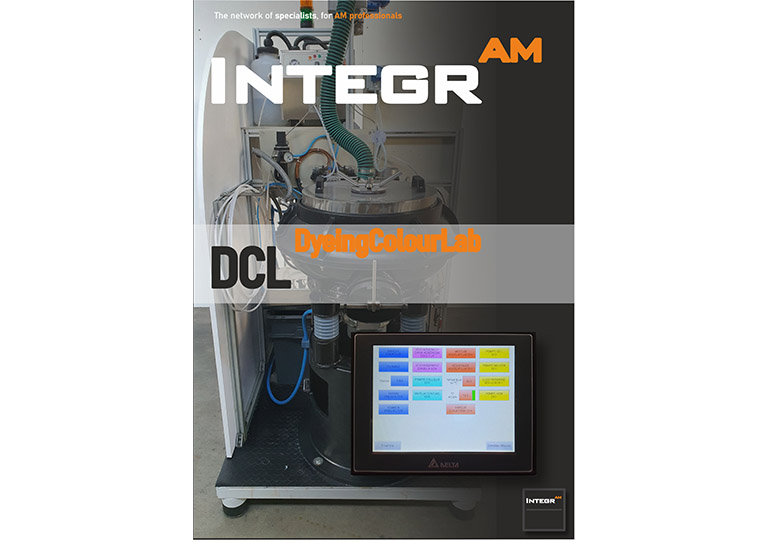

DCL Dyeing Colour Lab

A new range of pigments for dyeing has been improved and optimazed by DCL (Dyeing Colour Lab), in a Joint R&D program with the IntegrAM Team, special colouring pigments for any dyeing process – but with priority to the program: EXTRA-BLACK-AM.

Such an intense and deep black pigment, applied with the Steam Dyeing technology, provides innovation, low waste emission and circular economy concepts. In fact:

The result of this cooperation (The laboratory was set up at Rollwasch® – as a manufacturer of chemicals and compounds) is a very modern technology based on three strong points:

- The lowest possible carbon footprint and production of polluting substances or waste – compared with the classic technology about 10 to 20 times less polluting – this means a RATIONAL WASTE MANAGEMENT, with consequent reduced costs;

- Integrated process, 100% automated, including: 2A. Surface preparation; Heating up of the workpieces batch; 2B. Heating up of the workpieces batch; 2C. Steam DYEING EXTRA-BLACK-AM (with reduced quantity of consumables then low waste produced); 2D. Final Rinsing; 2E. Hot Air Drying of the workpieces batch;

- Repeatability towards recipes, with final automatic colour recovery, separated by the other phases (i.e.: rinsing)*;

* | In course of development the program to recover exhaust dyeing pigment as a second raw material to produce coloured products;

EXTRA-BLACK-AM technology has been presented at FORMNEXT 2024 in Frankfurt – Germany.

Besides the dark colour trend, we are going to present, in the beginning of 2025, the excellence of colour dyeing with: “Intense-CMY_AM”

To know more: https://surfacefinishing4t.com/am-post-process-dyeing-steam-dyeing/