BLT

Blasting Technology

Rollwasch® italiana

Blasting Technology

The programme of sandblasting and shot peening machines offered by Rollwasch® Italiana is the result of the continuous simplification of the market standards and of the careful application of reliable components, such as the suction cyclones, the supply turbines, the spare parts and the prompt assistance. Manual models with rotating basket of different capacities and sizes complement special machines manufactured according to the specific needs of the customer.

01

De-Pressure

Air Blasting (venturi)

02

Pressure Air Blasting

03

Wet

Blasting

04

Shot

Peening

05

Vibro Shot

Peening

06

Ultrasonic Shot Peening

De-pressure Air Blasting

The term “De-pressure Air Blasting” (Venturi) is one of the most popular blasting technologies well known all over the world.

Our offer in this contest is specialized for the industrial blasting units, where we try to excel for the high-quality standard and exclusivity of some specific options, like the LWS (Lining Wearing Sensor – Patented).

Our Lining Wearing Sensor LWS, offered as an option, is particularly interesting to detect when some critical protections or lining of panels and frames are going to wear too much.

This option is particularly interesting for: Aerospace, Medical, Food and similar.

The design of our Blasting cabinets is the result of a school of the made in Italy, with a long tradition of reliability, efficiency, user-friendliness for maintenance.

One example is the option of AS “antistatic bulbs”, when polymers, composites or electro-static sensible materials are processed.

Therefore, “De-pressure Air Blasting” (Venturi) at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting media can be used, except the metallic media and very high-density media.

Pressure Air Blasting

The term “Pressure Air Blasting” is one of the most popular blasting technologies, well known all over the world, where direct pressure over the blasting media is generating a higher kinetic energy, able to get best possible removal rate where needed.

Our offer in this contest is specialized for the industrial blasting units, where we try to excel for the high-quality standard and exclusivity of some specific options, like the LWS (Lining Wearing Sensor – Patented).

Our Lining Wearing Sensor LWS, offered as an option, is particularly interesting to detect when some critical protections or lining of panels and frames are going to wear too much.

This option is particularly interesting for: Aerospace, Medical, Food and similar.

The design of our Blasting cabinets is the result of a school of the made in Italy, with a long tradition of reliability, efficiency, user-friendliness for maintenance.

One example is the option of AS “antistatic bulbs”, when polymers, composites or electro-static sensible materials are processed.

Therefore, “Pressure Air Blasting” at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting media can be used, except the metallic media and very high-density media.

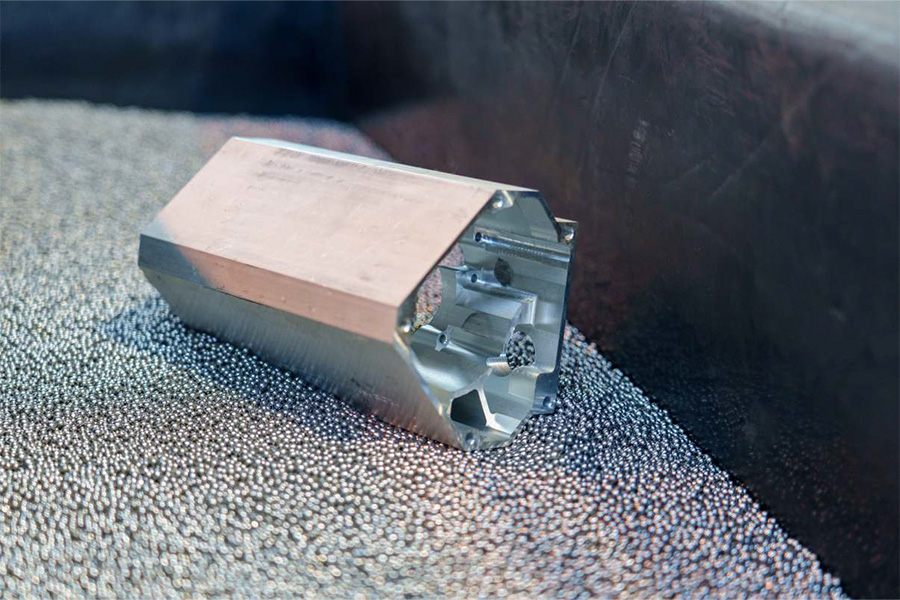

Wet Blasting

The term “Wet Blasting” is sometimes confused with vapor blasting, other times with water blasting, blasting without dust.

At Rollwasch® with this term we are able to offer both the following technologies:

1. traditional “Wet Blasting” technology, generated by the combination of compressed air combined with pump feeding the “slurry” (water mixed with blasting abrasives), to the blasting nozzle – then recycled “n” times over “n” sets of components;

2. innovative “Wet Blasting MF” technology, covered by the Patented technology “Micro Fluid” – in this case the use is mostly recommended for who does not want that pollutants are recycled together with the blasting media (Slurry).

Our offer in this contest is specialized for the industrial Wet Blasting units, where we try to excel for the high-quality standard and exclusivity of some specific options, like the LWS (Lining Wearing Sensor – Patented).

Our Lining Wearing Sensor LWS, offered as an option, is particularly interesting to detect when some critical protections or lining of panels and frames are going to wear too much.

This option is particularly interesting for: Aerospace, Medical, Food and similar.

The design of our Wet Blasting cabinets is the result of a school of the made in Italy, with a long tradition of reliability, efficiency, user-friendliness for maintenance.

Therefore, “Wet Blasting” at Rollwasch® is the perfect solution for daily professional use, where all kinds of Wet Blasting media can be used, except the metallic media and very high-density media.

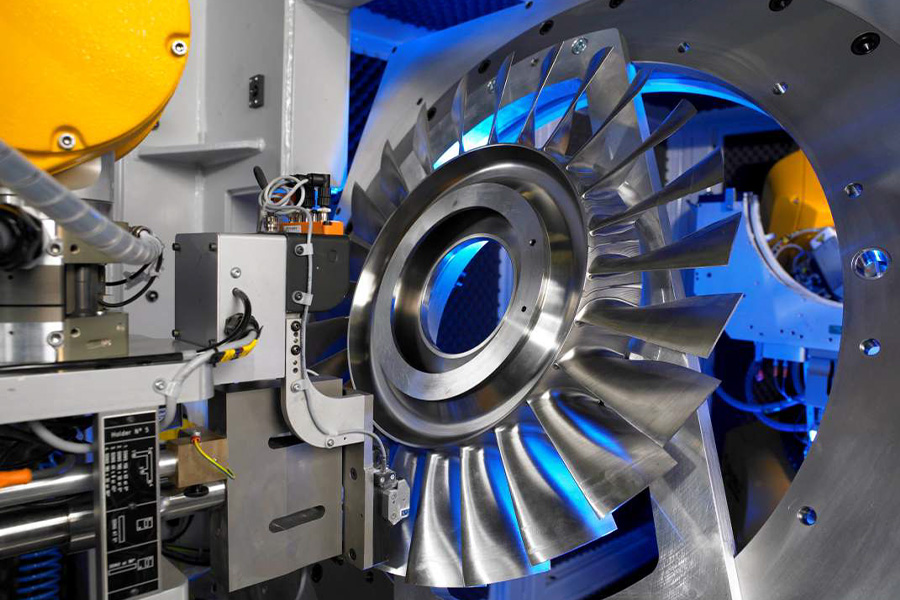

Shot Peening

The term “Shot Peening” is a very important technology, well known all over the world, where it is possible to have Compressed Air (See Pressure Blasting), to generate direct pressure over the blasting media or, alternatively, a Turbine to have the highest possible energy.

The main goal of “Shot Peening” is to increase fatigue strength and extend the life of mechanical components.

Our offer in this contest is specialized for the industrial shot peening systems, where we try to excel for the high-quality standard and exclusivity of some specific options, like the LWS (Lining Wearing Sensor – Patented).

Our Lining Wearing Sensor LWS, offered as an option, is particularly interesting to detect when some critical protections or lining of panels and frames are going to wear too much.

This option is particularly interesting for: Aerospace, Medical, Food and similar.

The design of our Shot peening systems is the result of a school of the made in Italy, with a long tradition of reliability, efficiency, user-friendliness for maintenance.

One example is the option of AS “antistatic bulbs”, when polymers, composites or electro-static sensible materials are processed.

Therefore, “Shot Peening” at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting media can be used, except the metallic media and very high-density media.

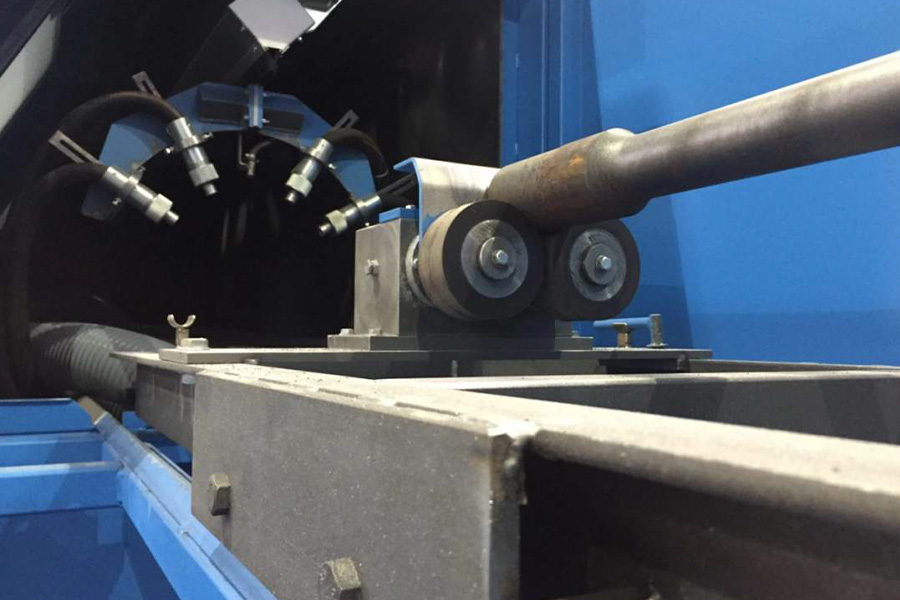

Vibro Shot PEENING

The term “Vibro Shot PEENING” is identifying the wide experience in the vibratory finishing technology of Rollwasch®, which started in the sixties with the sales of special vibratory finishing machines and first in the world with High Frequency motorvibrators at 3000 RPM, later on perfectioned and evoluted step by step with the integration of special frames to hold the components to be Shot Peened through Vibration at High Frequency.

The main goal of “Vibro Shot PEENING” is to increase fatigue strength and extend the life of mechanical components – avoiding to increase the surface roughness.

A peculiarity of the solutions offered in the portfolio of the “Vibro Shot PEENING” systems is the combination of several special versions of vibratory finishing machines (like, for example, the VSP trough vibrators with high frequency motorvibrators or double side vibrators), with suitable frames.

We cooperate with a highly qualified Laboratory operating with the most modern destructive and non destructive methods of quality check.

Ultrasonic Shot PEENING

The term “Ultrasonic Shot PEENING” USP, is identifying one of the most innovative, eco-friendly and efficient technologies, which Rollwasch® is just sharing with his European Business Partner who designs and produces these Leading-Edge systems.

The main goal of “Ultrasonic Shot PEENING” is to increase fatigue strength and extend the life of mechanical components, with limited or very limited alteration of the surface roughness.

A peculiarity of the solutions offered in the portfolio of the “Ultrasonic Shot PEENING” systems is the combination of several special versions of USP with high tech Robotic Islands.

We cooperate with a highly qualified Laboratory operating with the most modern destructive and non destructive methods of quality check.