ECS

Ecosonic Cleaning

Rollwasch® italiana

Ecosonic Cleaning

ECOSONIC technology is the demonstration of how multi-disciplinary Rollwasch® vision is able to be. A vision that has combined in this important project the best available resources at European level. First of all, ECOSONIC technology permits to accomplish complete systems of washing, rinsing and drying, in automatic and with investments on average more moderate than classic automatic systems available on the market. This result is due to the particular multitasking operating dynamic enabled by the combination of several factors as follows:

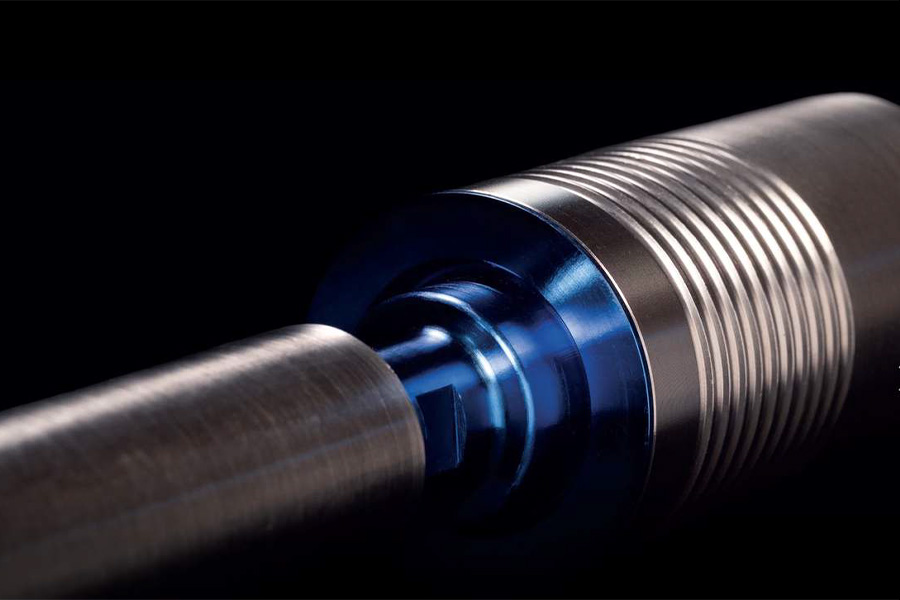

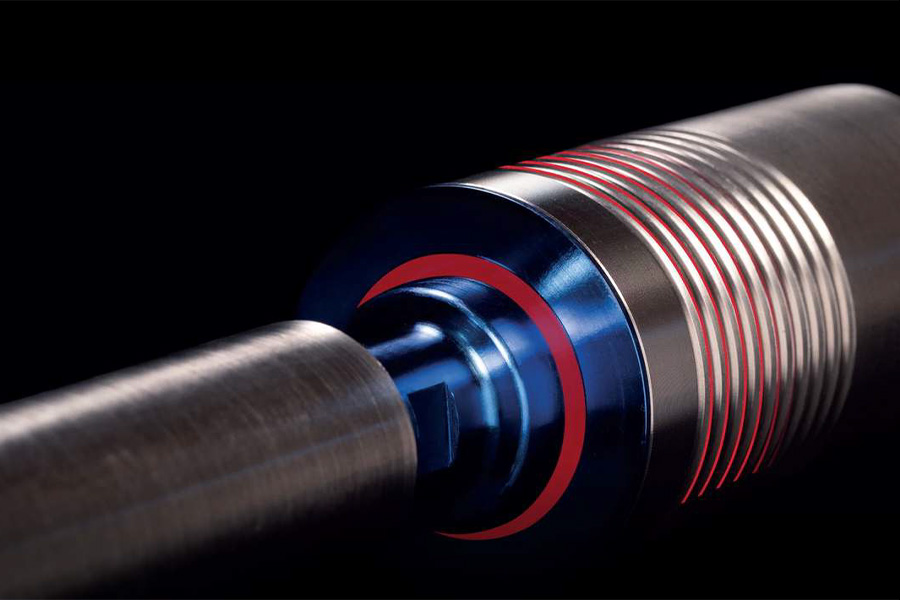

1. A circular vibrofinishing tank imposes to pieces that has to be washed a three-dimensional motion conveyed by special vectorial «media» called QF, with elastic and damping action – this thanks to a 1500 rpm motor-vibrator commanded by inverter;

2. A titanium sonotrode – conveniently placed few millimetres up the «media/pieces» mass and some centimetres down water level – produces an ultrasonic frequency equal to 20 Khz (twenty thousand times / second) and this engenders cavitation and deep cleaning in the involved components;

3. A hydraulic system made of tanks, pumps, filters and pneumatic discharging valves allows process liquids to effect separate and thermo-controlled washing and rinsing cycle phases, while a hot air insufflation system permits the final «dripping out» and drying phases of the washed parts.

01

Ecosonic 1Fq Technology

02

Ecosonic 2Fq Technology

03

Ecosonic 3Fq Technology

Ecosonic 1 fq Technology

The term “IWT” is the achronym acronym of “Industrial Washing Technology” where the “ECOSONIC Cleaning (1 sonotrode)” is identified by the combination of ULTRASONIC technology (single, dual or Multi frequency), applied with special sonotrodes to a circular vibratory finishing bowl.

Thanks to washing and rinsing heated tanks, that towards suitable pumps and filters are feeding the vibratory finishing bowl, the washing action can be done in fully automatic mode and in a reduced space.

In this bowl the parts are submerged in a first time with the heated washing water (including cleaning additives), in which they are rotating in a loop cycle for “n” times, during the programmed cycle times.

Our Ultrasonic Washing Systems are providing Multifrequency management at 20-135 kHz!

One example of washing cycle with 1 SONOTRODE:

- Automatic loading of washing water

- Washing phase (as example: 50 kHz)

- Automatic unloading of washing liquids

- Rinsing of parts

- Automatic unloading of rinsing liquids

- Hot Air blower in action for the Drying phase

The workpieces in the ECOSONIC machines can be pieces against pieces in mass, or even delicate components mixed with special vectorial “clean” media, that provide a 3D movement assistance to the workpieces during the ECOSONIC washing, rinsing and drying phases of each automatic cycle.

Rollwasch® is today offering a complete program of standard equipment, spacing from 25 to 50 and 120 liters, with the possibility to study bigger size solutions in tailor made versions as an option.

The technology of ultrasonic multifrequency is advantaged by integrated:

- Remote assistance

- Wifi

- Bluetooth

- Industry 4.0

Many options are available, like oil skimmer, special filters, water treatment plants to process the effluents.

So, “ECOSONIC Cleaning” is the perfect multifrequency solution for many apps, where final surface must be clean as much as possible.

Ecosonic 2 Fq Technology

The term “IWT” is the acronym of “Industrial Washing Technology” where the “ECOSONIC Cleaning (2 sonotrodes)” is identified by the combination of ULTRASONIC technology (single, dual or Multi frequency), applied with special sonotrodes to a circular vibratory finishing bowl.

Thanks to washing and rinsing heated tanks, that towards suitable pumps and filters are feeding the vibratory finishing bowl, the washing action can be done in fully automatic mode and in a reduced space.

In this bowl the parts are submerged in a first time with the heated washing water (including cleaning additives), in which they are rotating in a loop cycle for “n” times, during the programmed cycle times.

Our Ultrasonic Washing Systems are providing Multifrequency management at 20-135 KHz!

One example of washing cycle with 2 SONOTRODES:

- Automatic loading of washing water

- Washing phase (as example: 50 kHz)

- Washing phase (as example: 80 kHz)

- Automatic unloading of washing liquids

- Rinsing of parts (as example: 80 kHz)

- Rinsing of parts with purified water (third optional tank)

- Automatic unloading of rinsing liquids

- Hot Air blower in action for the Drying phase

The workpieces in the ECOSONIC machines can be pieces against pieces in mass, or even delicate components mixed with special vectorial “clean” media, that provide a 3D movement assistance to the workpieces during the ECOSONIC washing, rinsing and drying phases of each automatic cycle.

Rollwasch® is today offering a complete program of standard equipment, with double sonotrode, spacing from 50 to 120 liters, with the possibility to study bigger size solutions in tailor made versions as an option.

The technology of ultrasonic multifrequency is advantaged by integrated:

- Remote assistance

- Wifi

- Bluetooth

- Industry 4.0

Many options are available, like oil skimmer, special filters, water treatment plants to process the effluents.

So, “ECOSONIC Cleaning” is the perfect multifrequency solution for many apps, where final surface must be clean as much as possible.

Ecosonic 3 Fq Technology

The term “IWT” is the acronym of “Industrial Washing Technology” where the “ECOSONIC Cleaning (3 sonotrodes)” is identified by the combination of ULTRASONIC technology (single, dual or Multi frequency), applied with special sonotrodes to a circular vibratory finishing bowl.

Thanks to washing and rinsing heated tanks, that towards suitable pumps and filters are feeding the vibratory finishing bowl, the washing action can be done in fully automatic mode and in a reduced space.

In this bowl the parts are submerged in a first time with the heated washing water (including cleaning additives), in which they are rotating in a loop cycle for “n” times, during the programmed cycle times.

Our Ultrasonic Washing Systems are providing Multifrequency management at 20-135 KHz!

One example of washing cycle with 3 SONOTRODES:

- Automatic loading of washing water

- Washing phase (as example: 50 kHz)

- Washing phase (as example: 80 kHz)

- Washing phase (as example: 120 kHz)

- Automatic unloading of washing liquids

- Rinsing of parts (as example: 80 kHz)

- Rinsing of parts with purified water (third optional tank)

- Automatic unloading of rinsing liquids

- Hot Air blower in action for the Drying phase

The workpieces in the ECOSONIC machines can be pieces against pieces in mass, or even delicate components mixed with special vectorial “clean” media, that provide a 3D movement assistance to the workpieces during the ECOSONIC washing, rinsing and drying phases of each automatic cycle.

Rollwasch® is today offering a complete program of standard equipment, with triple sonotrode, starting from 120 liters, with the possibility to study bigger size solutions in tailor made versions as an option.

The technology of ultrasonic multifrequency is advantaged by integrated:

- Remote assistance

- Wifi

- Bluetooth

- Industry 4.0

Many options are available, like oil skimmer, special filters, water treatment plants to process the effluents.

So, “ECOSONIC Cleaning” is the perfect multifrequency solution for many apps, where final surface must be clean as much as possible.