The new Superminor Sm3 version represents the best that can currently be expected from medium-sized finishing machines. The capacity of around a hundred liters may seem limiting, but it actually delivers great performance in terms of the loading, with a capacity of up to 500 kg. This without altering its balance or performance.

Features of a basic wet SM3-D-120 machine, with 1 filter/drain valve:

- The drain filter is perfectly positioned horizontally at the bottom of the tank, not laterally as in previous SMR versions, so it can ensure a definitely better wastewater discharge.

- Soft materials protected by elastic and flexible coverings, in order to ensure the safety of the operator.

- Two tie rods are applied for the correct securing of the tank for the transportation of the machine.

- The discharge port is made of PU and stainless steel, flared and prepared for the possible insertion of a wear sensor (optional) WS© series (Wear Sensor – patented).

- Wide inspection opening to access the adjustment of the vibrator motor (lower eccentrics).

- Practical screw cap in PU normally applied in 2 points (one dedicated to the standard shower on the wet versions). Depending on the versions, these provisions can have a cap or other optional connectors.

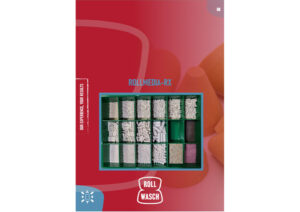

Optional features of an SM3-D-120 machine:

- The strong point of the new SM3 series is undoubtedly its constructive modularity, allowing it to install 1, 2, or 3 exhaust filters.

- These filters can be connected to ‘GM’ valves for always-open discharge, or to ‘PRO’ valves with manual screw control, or finally, to ‘PNEU’ valves with pneumatic opening and closing.

Having three exhaust filters positioned horizontally at the bottom of the tank offers undeniable advantages in both wet and dry processes for a multitude of reasons, including:

Optional features of a SM3-D-120 machine:

- Connect each discharge to a different collection point, therefore – for example in a wet process, one discharge connected to a discharge collection point to be subjected to oil separation, a second to a closed-circuit centrifugal filter, and a third to a recycling tank containing protective or anti-corrosive additives;

- In the VibroBLAST vibro-sandblasting processes, utilize three exit points to favor the use of both higher pressures and a double sandblasting nozzle;

The Superminor SM3 machines are always available for a demo at our showroom.