VBT

Vibroblast Technology

Rollwasch® italiana

Vibroblast Technology

Rollwasch® introduces a new surface finishing technology: VibroBLAST, result of three patent applications and about 8 years of research, in addition to a close collaboration with sandblasting and aspiration/air filtration specialists. Everything strictly «made in Italy». A patent for the VibroBLAST process, a patent for the specific use for special Additive Manufacturing «post-processes», like the finishing strategies which prevent the pollution of the additive components and, finally, a patent specifically dedicated to the special vibrofinishing elastic media of QuattroFinish or QF. But what distinguishes the VibroBLAST process from a normal sandblasting or vibrofinishing process? And why choose this «hybrid» process, a technology resulting from the synergy between two known techniques? Get in touch with us! Many processes based today on two different operations, one of which carried out manually, can be executed automatically with VibroBLAST with a single machine, and with only one process. In any case it is very important to underline that, although this technology includes ALSO solutions dedicated to the Additive Manufacturing POST PROCESSES, it offers advantages to the most varied sectors of use, both for metallic components and for polymers and also for other materials, such as wood, ceramics, composites, not necessarily manufactured in Additive, but also die-casted, injection-molded, milled, from laser cutting, from water-cutting, from oxygen-flame cutting, hot moulded, forged, etc.

The development of the VibroBLAST programme

Rollwasch® programmed the presentation of VibroBLAST solutions over time, as represented in the following diagram. Some special configurations, like the VibroBLAST ICE line, are not reported in the diagram even if programmed by time.

01

De-Pressure Vibroblast DP (venturi)

02

Pressure Vibroblast PR

03

Vibroblast

wet

04

Vibroblast

Ice

05

Vibroblast

Wheel

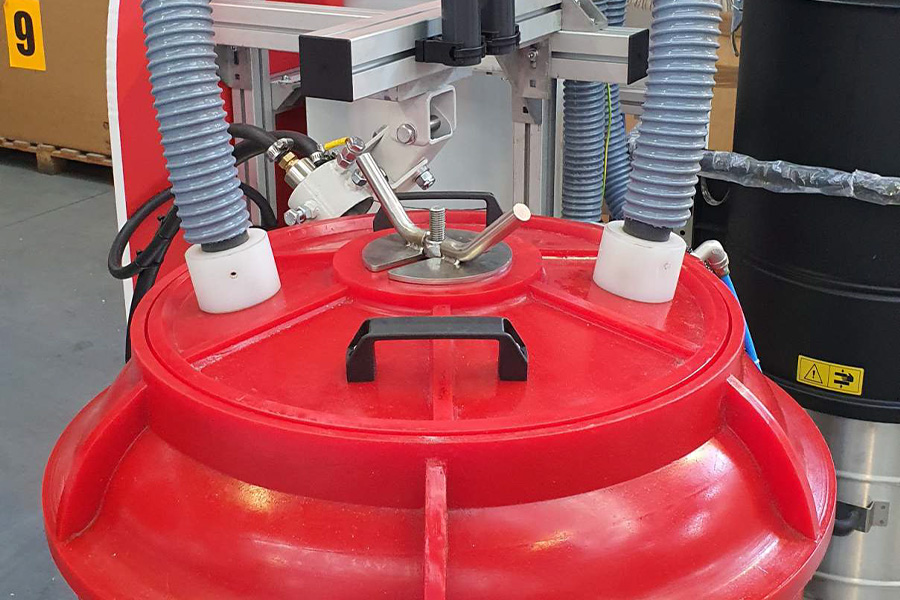

De-Pressure Vibroblast DP (Venturi)

The term “De-pressure VibroBLAST DP” (Venturi) is one of the most INNOVATIVE blasting technologies, where the combination of vibratory finishing and blasting opens the door to a completely new world of possible uses.

One of the main goals of the “VibroBLAST DP” is to offer an AFFORDABLE TECHNOLOGY to do, in automatic, the blasting operations that are normally made by hand.

The best alternative to blast by hand because parts are delicate, because they are different from today and tomorrow and robot is too expensive to buy and to program time to time. With the aid of special vectorial media with an elastic body, the parts are moved three dimensionally inside the VibroBLAST equipment and exposed to the blasting nozzle in order to receive the blasting media – in short time (average 15’ minutes) the 100% of the surface of each part involved into a VibroBLAST process is done.

Our offer of “VibroBLAST DP” machines is as good for metal components, as for polymers and composites, wood and ceramic.

The design of our “VibroBLAST DP” machines is the result of an intensive activity of R&D that Rollwasch® continuously renews, year after year, since 1950.

Therefore, “VibroBLAST DP” at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting media can be used, except the metallic media and very high-density media.

Pressure Vibroblast PR

The term “Pressure VibroBLAST PR” is one of the most INNOVATIVE blasting technologies, where the combination of vibratory finishing and pressure blasting opens the door to a completely new world of possible uses.

One of the main goals of the “VibroBLAST PR” is to offer an AFFORDABLE TECHNOLOGY to do, in automatic, the pressure blasting operations that are normally made by hand.

The best alternative to blast by hand because parts are delicate, because they are different from today and tomorrow and robot is too expensive to buy and to program time to time. With the aid of special vectorial media with an elastic body, the parts are moved three dimensionally inside the VibroBLAST equipment and exposed to the blasting nozzle in order to receive the blasting media – in short time (average 15’ minutes) the 100% of the surface of each part involved into a VibroBLAST process is done.

Our offer of “VibroBLAST PR” machines is as good for metal components, as for polymers and composites and ceramic.

The design of our “VibroBLAST PR” machines is the result of an intensive activity of R&D that Rollwasch® continuously renews, year after year, since 1950.

Therefore, “VibroBLAST PR” at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting media can be used, including also the metallic media.

Vibroblast Wet

The term “VibroBLAST Wet” is one of the most INNOVATIVE blasting technologies, where the combination of vibratory finishing and wet blasting opens the door to a completely new world of possible uses.

At Rollwasch® with this term we are able to offer both the following technologies:

1. VibroBLAST WET based on traditional “Wet Blasting” technology, generated by the combination of compressed air combined with pump feeding the “slurry” (water mixed with blasting abrasives), to the blasting nozzle – then recycled “n” times over “n” sets of components;

2. VibroBLAST WET based on innovative “Wet Blasting MF” technology, covered by the Patented technology “Micro Fluid” – in this case the use is mostly recommended for who does not want that polluctant are recycled together with the blasting media (Slurry).

One of the main goals of the “VibroBLAST WET” is to offer an AFFORDABLE TECHNOLOGY to do, in automatic, the blasting operations that are normally made by hand.

The best alternative to blast by hand because parts are delicate, because they are different from today and tomorrow and robot is too expensive to buy and to program time to time. With the aid of special vectorial media with an elastic body, the parts are moved three dimensionally inside the VibroBLAST equipment and exposed to the blasting nozzle in order to receive the blasting media – in short time (average 15’ minutes) the 100% of the surface of each part involved into a VibroBLAST process is done.

Our offer of “VibroBLAST WET” machines is as good for metal components, as for polymers and composites, wood and ceramic.

The design of our “VibroBLAST WET” machines is the result of an intensive activity of R&D that Rollwasch® continuously renews, year after year, since 1950.

Therefore, “VibroBLAST WET” at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting media can be used, except the metallic media and very high-density media.

Vibroblast Ice

The term “VibroBLAST ICE” is almost one of the most INNOVATIVE blasting technology, where the combination of vibratory finishing and ICE blasting open the door to a completely new world of possible uses.

At Rollwasch® with this term we are able to offer both kinds of this technologies:

1. VibroBLAST ICE based on traditional “ICE Blasting” technology, generated by the combination of compressed air combined with dry ice pellets (based on CO2);

2. VibroBLAST ICE based on innovative “ICE Blasting Nitrogen” technology, generated by the combination of compressed air combined with special blasting media and a cryogenic environment determined by the use of Nitrogen;

One of the main goal of the “VibroBLAST ICE” is to offer an AFFORDABLE TECHNOLOGY to do, in automatic, the blasting operations that are normally made by hand.

The best alternative to blast by hand because parts are delicate, because they are differend from today and tomorrow and robot is too expensive to buy and to program time to time. With the aid of special vectorial media with an elastic body, the parts are moved three dimensionally inside the VibroBLAST equipment and exposed to the blasting nozzle in order to receive the blasting media – in short time (average 15’ -25’ minutes) the 100% of the surface of each part involved into a VibroBLAST process is done.

Our offer of “VibroBLAST ICE” machines is as good for elastomers, as for polymers and composites.

The design of our “VibroBLAST ICE” machines is the result of an intensive activity of R&D that Rollwasch® continuously renew, year after year, since 1950.

Therefore, “VibroBLAST ICE” at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting media can be used, except the metallic media and very high density media.

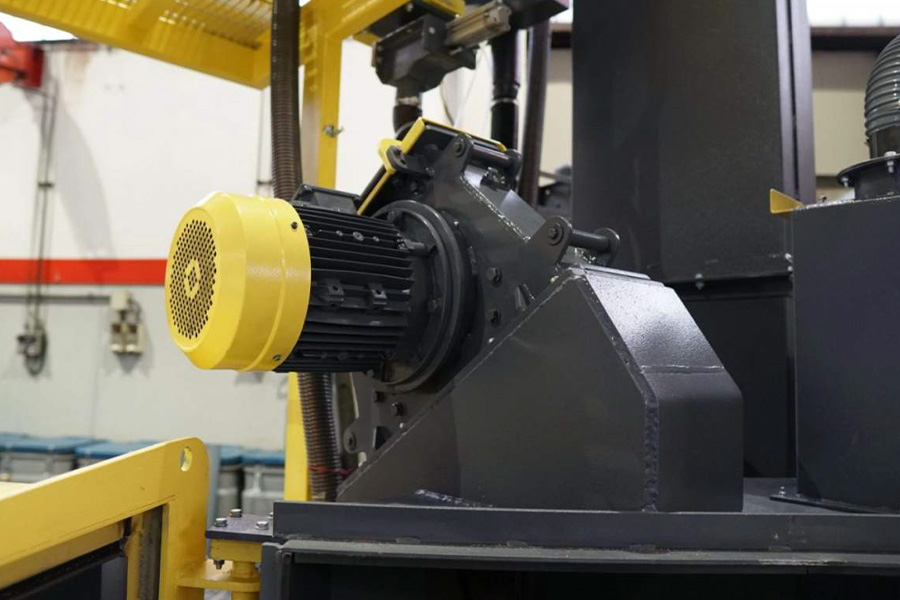

Vibroblast Wheel

The term “VibroBLAST WHEEL” is one of the most INNOVATIVE blasting technologies, where the combination of vibratory finishing and wheel or turbine blasting opens the door to a completely new world of possible uses.

One of the main goals of the “VibroBLAST WHEEL” is to offer an AFFORDABLE TECHNOLOGY to do, in automatic, the wheel or turbine blasting operations that are normally made with traditional and more expensive systems.

Our offer of “VibroBLAST WHEEL” machines is as good for metal components, as for composites and superalloys.

The design of our “VibroBLAST WHEEL” machines is the result of an intensive activity of R&D that Rollwasch® continuously renews, year after year, since 1950.

Therefore, “VibroBLAST WHEEL” at Rollwasch® is the perfect solution for daily professional use, where all kinds of blasting metallic media can be used.