Home » Specialisation technological macro-areas » MSF – Mass Surface Finishing » The Sicor Drying

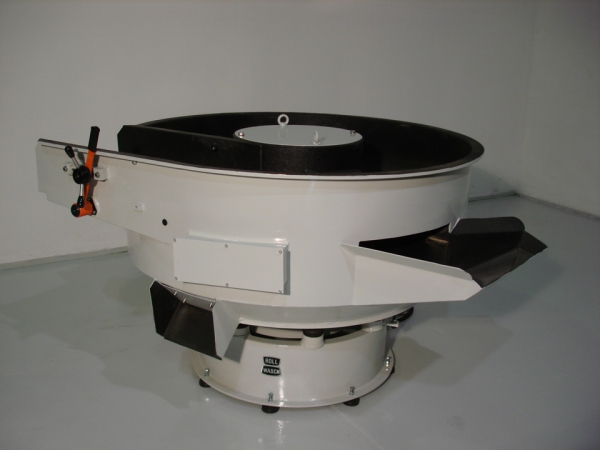

The drying of the absorbent grit is obtained through the contact with a series of resistances placed under the fixed grid, that is immediately after the ascending ramp for the pieces. The design of the Sicor dryers allows the perfect compatibility with the most important and modern Rollwasch®’s machines. According to the type and quantity of pieces to be dried daily, the tank of the Sicor series can be with or without (/SR) the antishock lining. The antishock linings of the Sicor machines can be made of vulcanized rubber (/G) of special composition and thickness, or in sprayed PU (/SPU) or in hot moulded PU (/P – only AS3). The machine can be equipped with the most suitable electric control according to the table reported in the catalogue that you can find below; moreover, the machine can also be supplied with different accessories. It is possible to set the Sicor machines with different AUTOMATION levels, both as a single unit and as a component of SYSTEMS of various types. Some examples are the double automatic flap, able to run batch cycles of variable time and then unload the entire content without any sticking problem. The useful optional thermostat assures cycles with constant and controlled temperatures. The OUTRACE external pre-dripping channel, available on all the PRO machines, assures efficient continuous cycles also of difficult articles. The UNIVAR-PVC rinsing tank allows the unloading of passivated or protected articles, not only dried.