Home » Specialisation technological macro-areas » COAT – Coating Technology

Products and Specialisation Technological Macro-Areas

- MSF – Mass Surface Finishing

- PMRF – Precision Material Removal Finishing

- LERFIT – Leading Edge Robotic Finishing Tech

- BLT – Blasting Technology

- VBT – VibroBLAST Technology

- DBT – DragBLAST Technology

- IWT – Industrial Washing Technology

- ECS- ECOSONIC Cleaning

- E-LYTE – Electro Chemical Technology

- COAT – Coating Technology

- WTF – Water Treatment & Filtering Technology

- QFM – Quattrofinish Special Media

- KEM – Rollkemik Compounds

- ROLLMEDIA – Media for Surface Finishing

- ENG – Engineering & Industry 4.0

COAT – COATING TECHNOLOGY

Rollwasch® has developed extremely interesting, innovative, automatic and safe coating solutions.

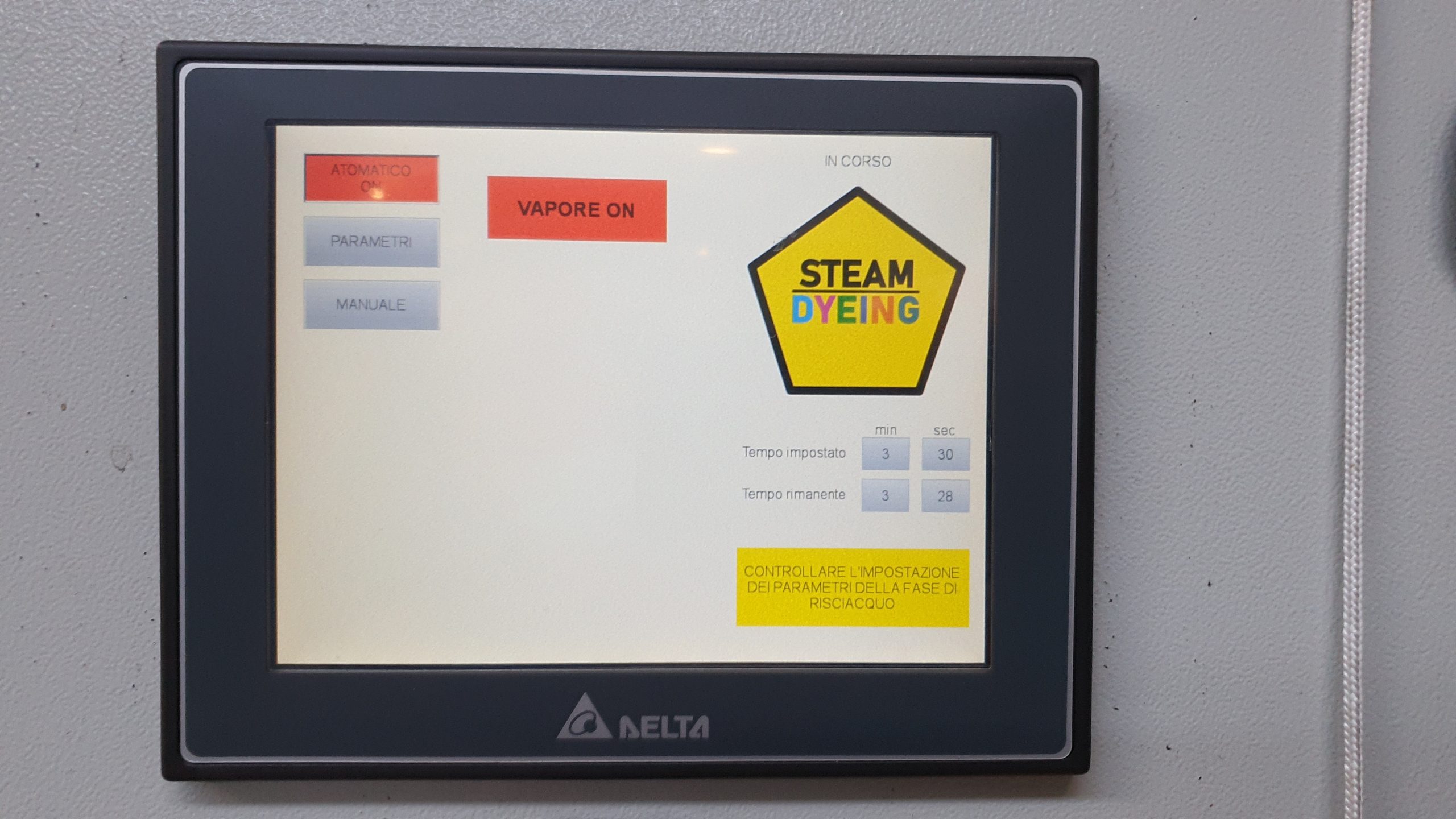

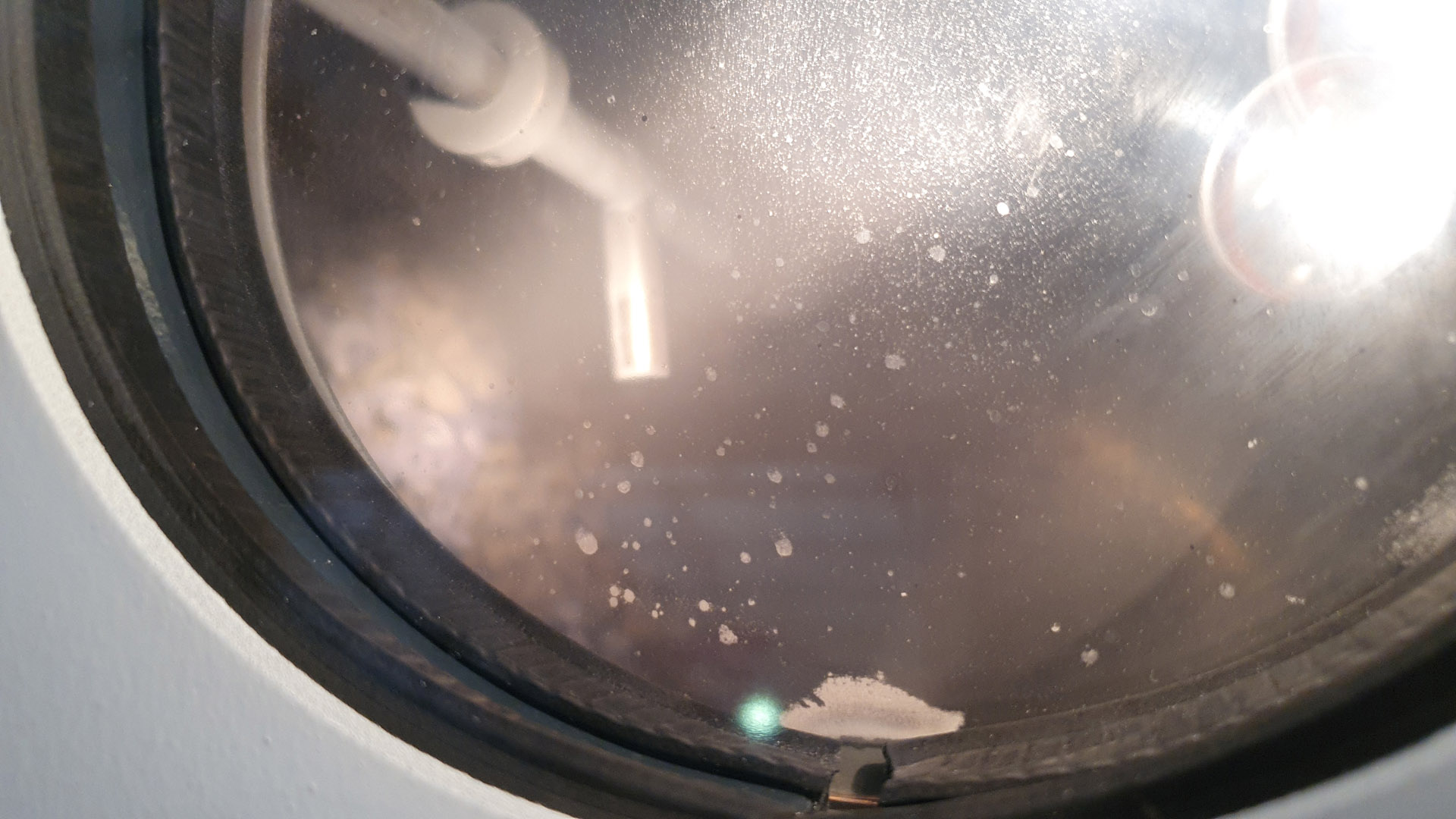

On one hand, Steam DYEING technology allow to steam dye components in plastic materials or in composite materials with polymers base.

On the other hand, RotoPAINT technology permits the painting or the coating with various composites (for example lubricating or waterproofing) through rotary barrels of special conception.

The two technologies differ in the type of affixed substances and in the way the colour is applied to the surface.

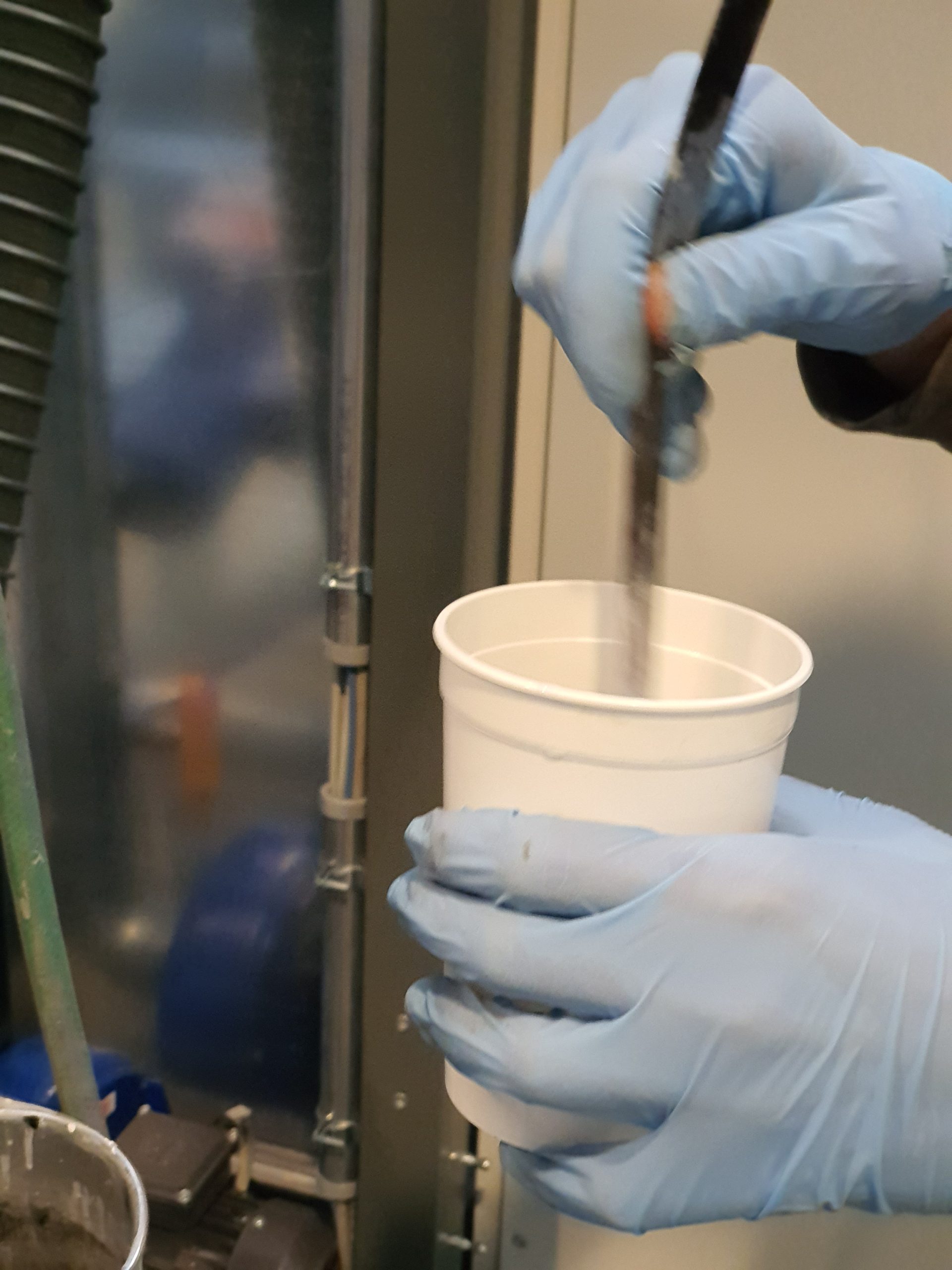

Indeed, Steam DYEING technology uses water soluble colourants to dye polymers preheated with dry saturated steam, then undergone to steam jets mixed with colourant of Smart DYEING range and then dried.

To give a practical example, today a dyeing classic process envisages the immersion of polymers in a heated liquid made of 1 part of concentrated dye and 9 parts of hot water (e.g. 90°C) – therefore using a medium-small 30-litre tank, you will use 3 kg of concentrated colourant.

The same Steam dyeing process in a 36-litre tank involves te use of pre-diluted dye in water (e.g. 1 part of dye and two of water), then added for the dyeing phase in quantities that normally do not exceed 600 gr (hence only 200 gr of concentrated colourant) – this reduces the dye consumption from 3000 to 200 gr, hence about 15 times. We can state that variables can reach extremes between 10 and 20 times if compared to traditional processes.

RotoPAINT technology is altogether a painting process with large use of solvent base paints. It can be applied to metal, plastic, wood and composite materials components; RotoPAINT rotary barrels are extremely flexible, efficient and, mainly, safe machines.